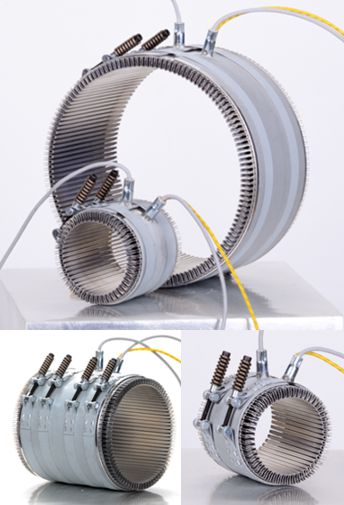

Air cooled band heaters made from aluminium (EP 0898139 / JP 3032748 / US 6095236):

Product description:

Air is axially streamed through this air cooled band heater which is designed for unbroken, very precise temperature control along the entire length of the plasticating cylinder. The length of the individual elements can be manufactured to fit the zone length down to the millimeter, in one or several parts. The fastening technology for the mounting of the temperature sensor is integrated into the cooling element. Depending on the cooling performance in the zone, several cooling elements can be stacked on one another. Thanks to the performance capacity of our elements, even liquid-controlled cooling solutions can be successfully replaced with our air cooled elements. This configuration will optimise the price-performance ratio of the entire control path.

Scope of application:

The air cooled band heaters are primarily used for extrusion.

Advantages:

- Optimal heat transfer results in a minimal heating period during start-up as well as an optimum cooling performance during production

- Minimal lagging of the extruder pipe due to balanced, axial air flow

- Optimal heating and temperature run

- The energy efficiency has been officially tested and optimised as FEA Model

- Can be used even in tight installation spaces

- The outer diameter of the extruder pipe allows for a large manufacturing tolerance

- This variant will guarantee highly precise temperature control in any situation during the entire manufacturing process

- Area of application from the feed zone to the output zone

- Simple assembly

Product data:

Dimensions:

| Cylinder outer diameter: | 60 – 300 mm (Pipe diameter tolerance 1mm) |

| Partial segments also possible: | Radius 30 – 150 mm |

| Cooling cuff height: | 10 mm; stackable |

| Heating cuff height: | 2,5 mm |

| Air cooled band heater width:td> | 70 – 190 mm |

Temperatures:

| Max. temperature: | 450 °C (higher temperatures possible upon request) |

Electrical data:

| Max. electr. output: | 5 W/cm2 heated area for small diameters 3,2 W/cm2 heated area for large diameters (higher power density possible upon request) |

| Service voltage: | all |

| Testing voltage: | 1500 V |

| Insulating resistance: | >10 MΩ |

Cooling capacity:

| Cooling capacity for air: | 1-stage: 7.6 W/cm2 cylinder surface 2-stage: 11.4 W/cm2 cylinder surface |

Further technical data, such as ideal air speed and air mass flow, step response and control curve of these elements, are available upon request.